Custom Mechanical Testing - 3D Printing - Biofabrication

I'm a Bioengineering Ph.D. candidate at Stanford developing low-cost, high-throughput 3D-printing technologies for generating cardiac tissues in Mark Skylar-Scott's 3D-Bioprinting Lab.

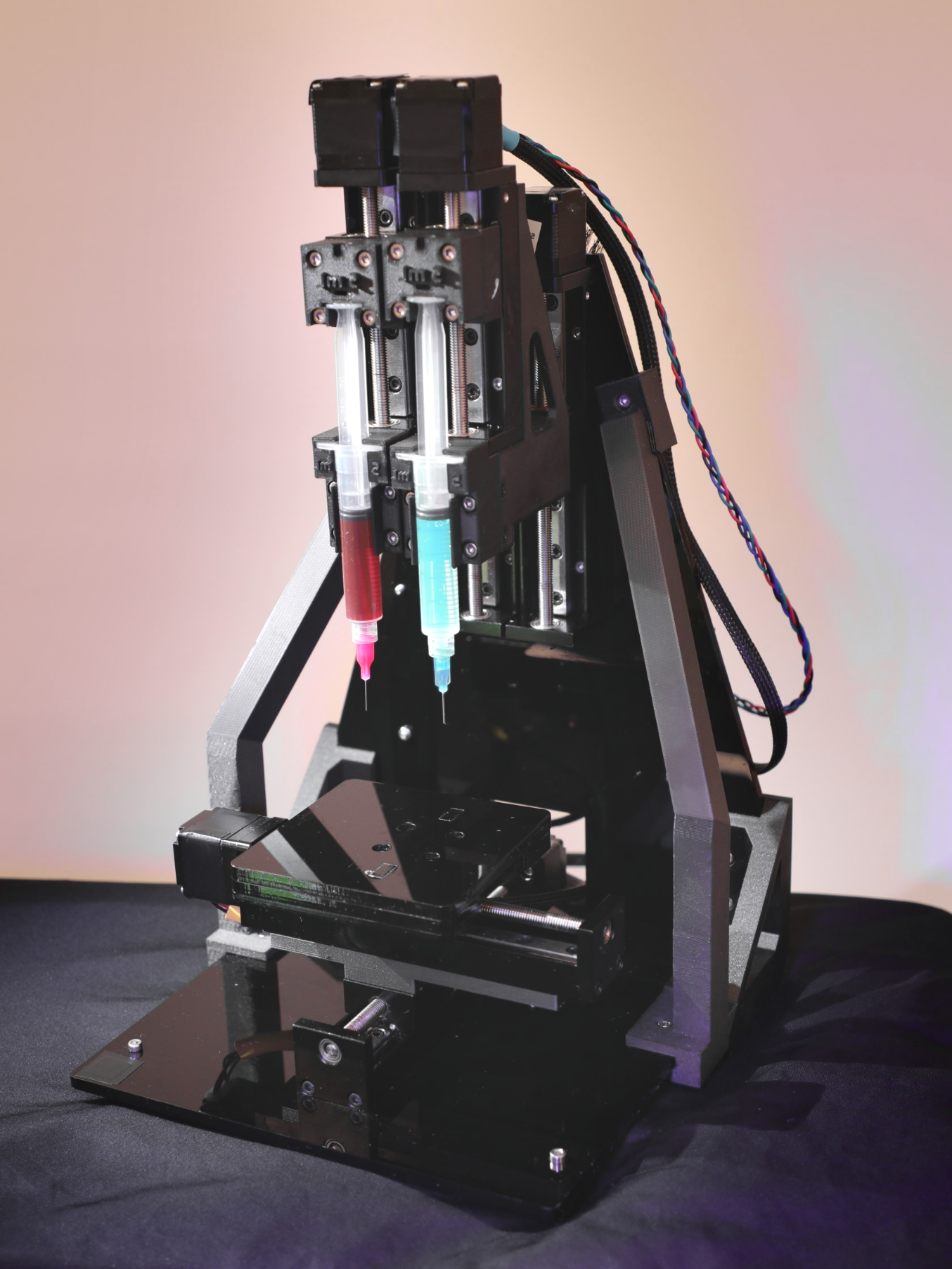

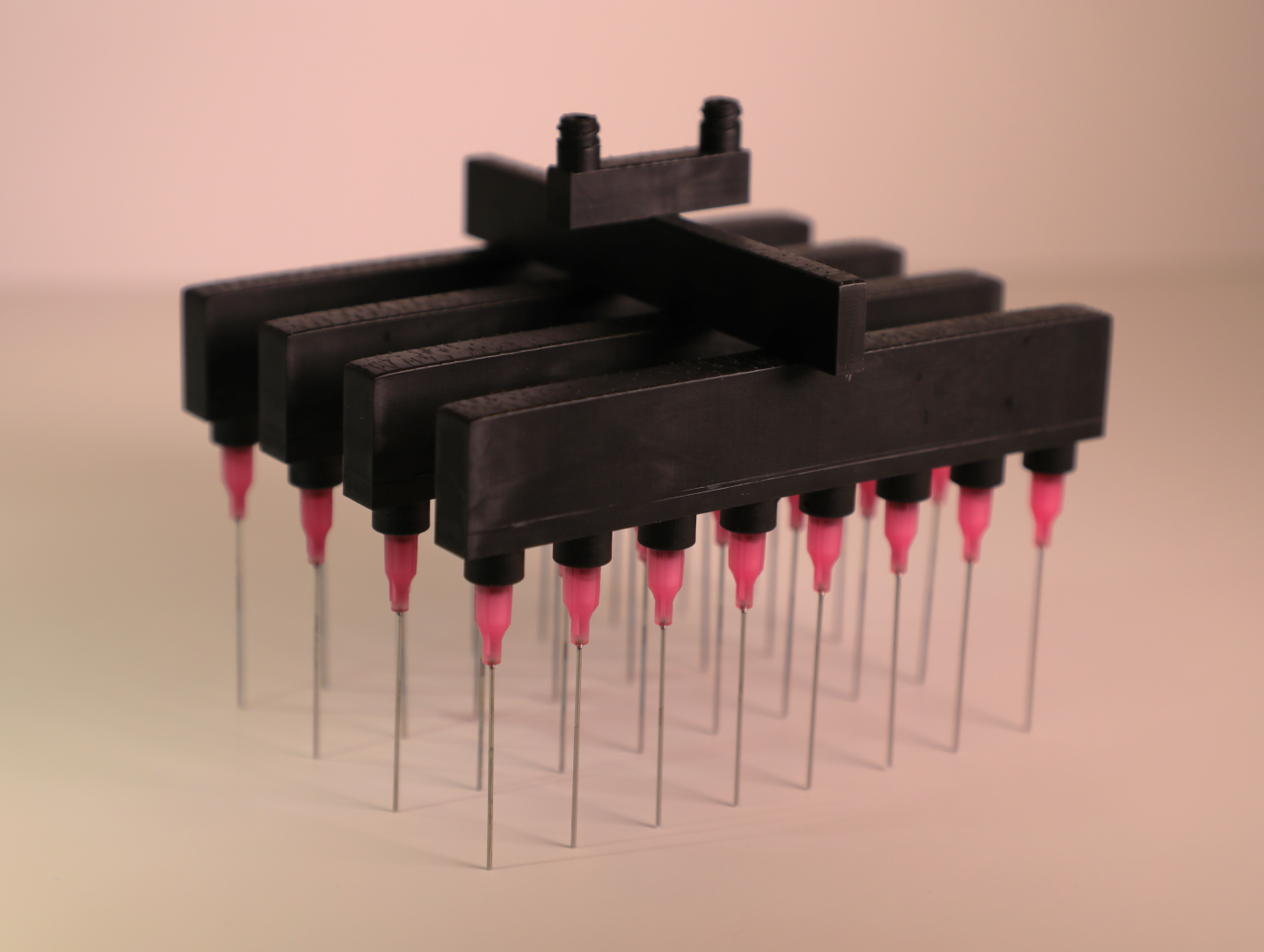

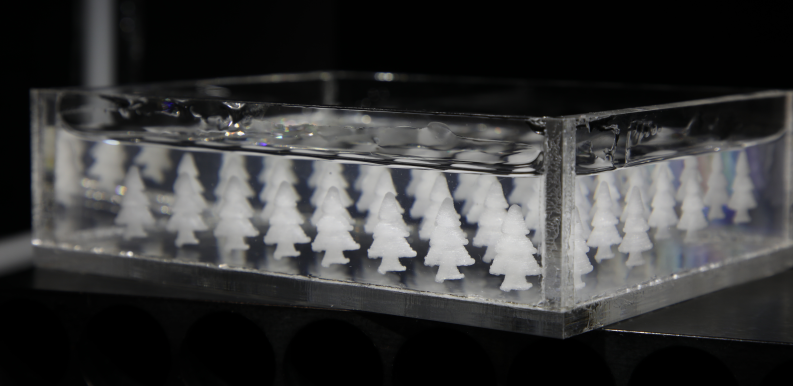

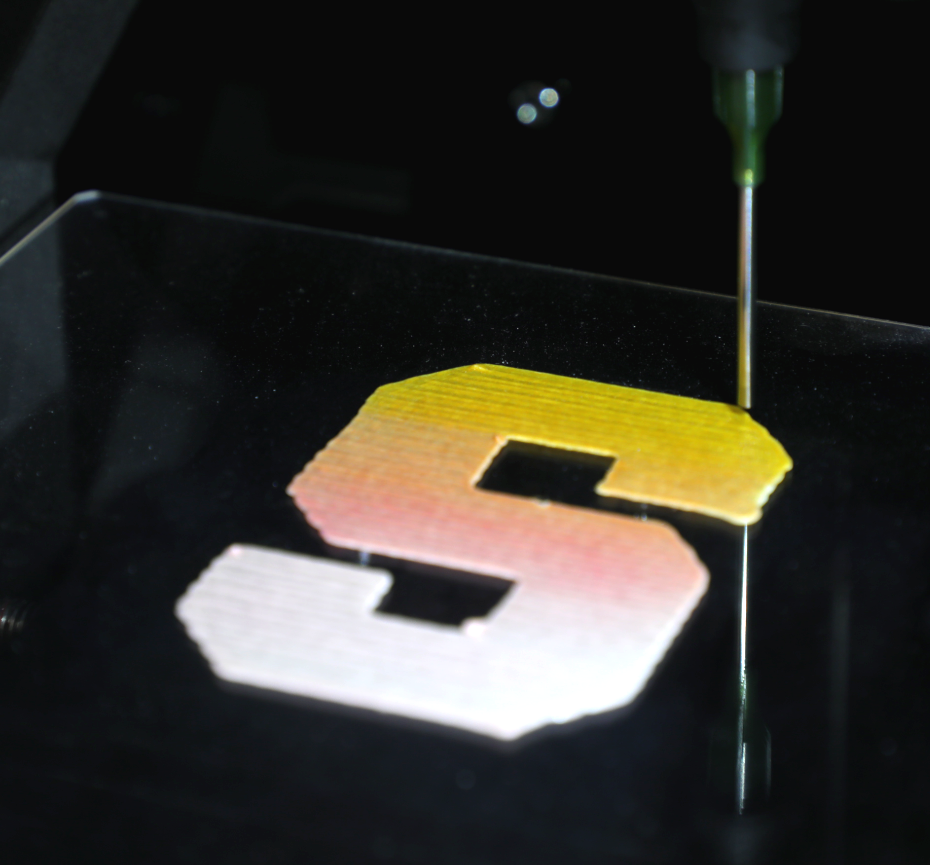

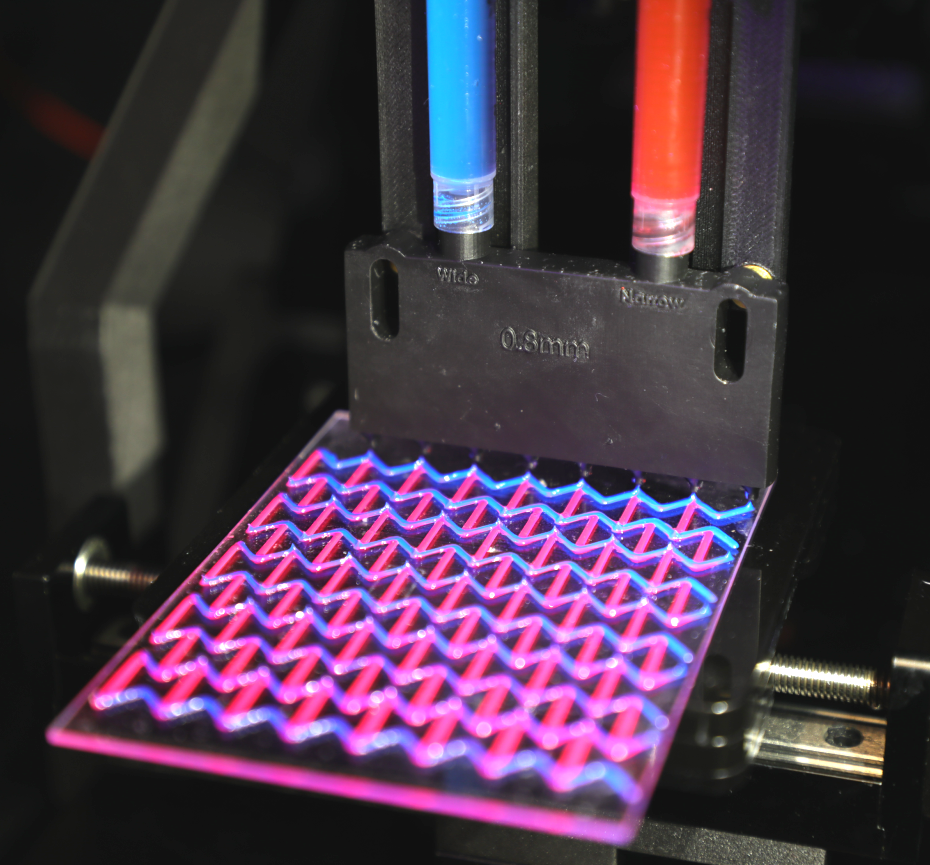

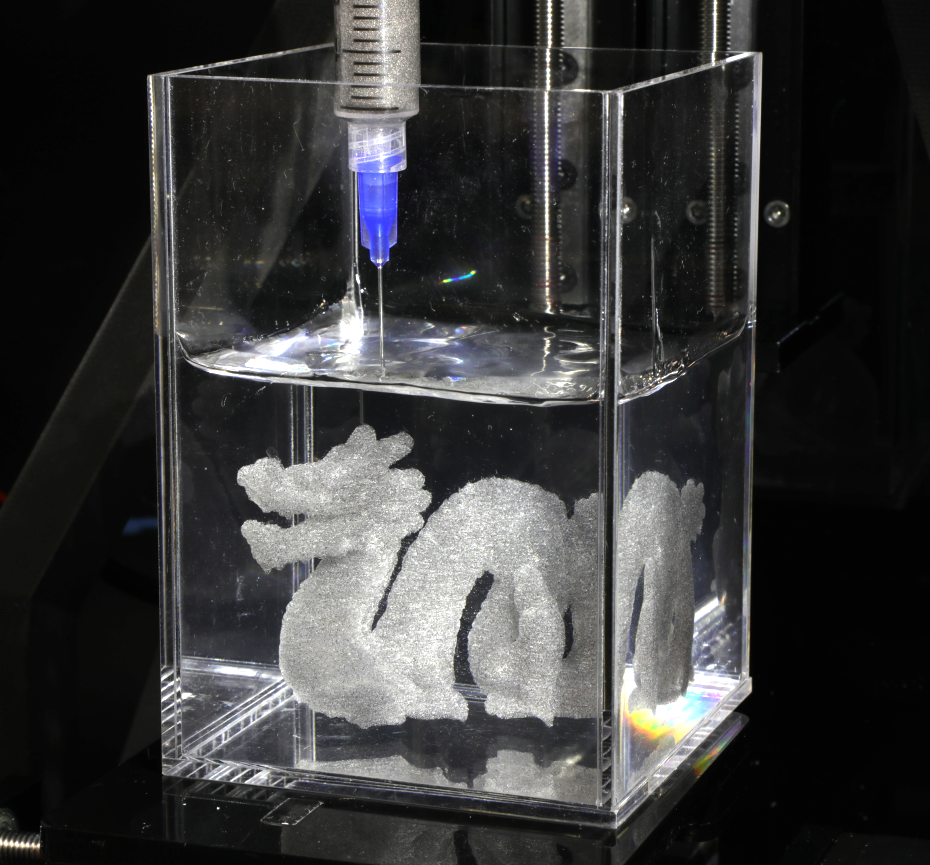

I have extensive experience in 3D computer-aided design (CAD), mechanical device prototyping, 3D printing, and biofabrication. I use 3D bioprinting technologies, particularly novel multinozzle printheads, to create soft-material structures such as silicone elastomers, photocurable hydrogels, and cell-laden engineered tissues. My work includes printing custom-geometry heart valves and small-scale cardiac and stem cell tissue models, which I use to study function, growth, and maturation.

I am seeking to bridge these engineering disciplines to develop impactful technologies in robotics, biotech, medical devices, electronics, and beyond.

Programmable 3D cell alignment of bioprinted tissue via soft robotic dynamic stimulation.

L. Rosalia, K. Mosle, S. Sinha, Y.Y. Du, F. Solberg, A. Jia, J.D. Weiss, T. Tam, J.E. Herrmann, M.R. Cutkosky, M. Skylar-Scott.

BioRxiv 2024. https://doi.org/10.1101/2024.11.03.621771

Biomanufacturing human tissues via organ building blocks.

K.J. Wolf*, J.D. Weiss*, S.G.M. Uzel, M.A. Skylar-Scott, J.A. Lewis.

Cell Stem Cell 2022. https://doi.org/10.1016/j.stem.2022.04.012

A Microwell Cell Capture Device Reveals Variable Response to Dobutamine in Isolated Cardiomyocytes.

J.A. Clark, J.D. Weiss, S.G. Campbell.

Biophysical Journal 2019. https://doi.org/10.1016/j.bpj.2019.08.024

In my free time, I enjoy guitar 🎸, chess 👑, running 🏃♂️, and Olympic weightlifting 🏋️.

I also tutor up to college-level calculus, physics, and other mathematics. Feel free to contact me with inquiries.